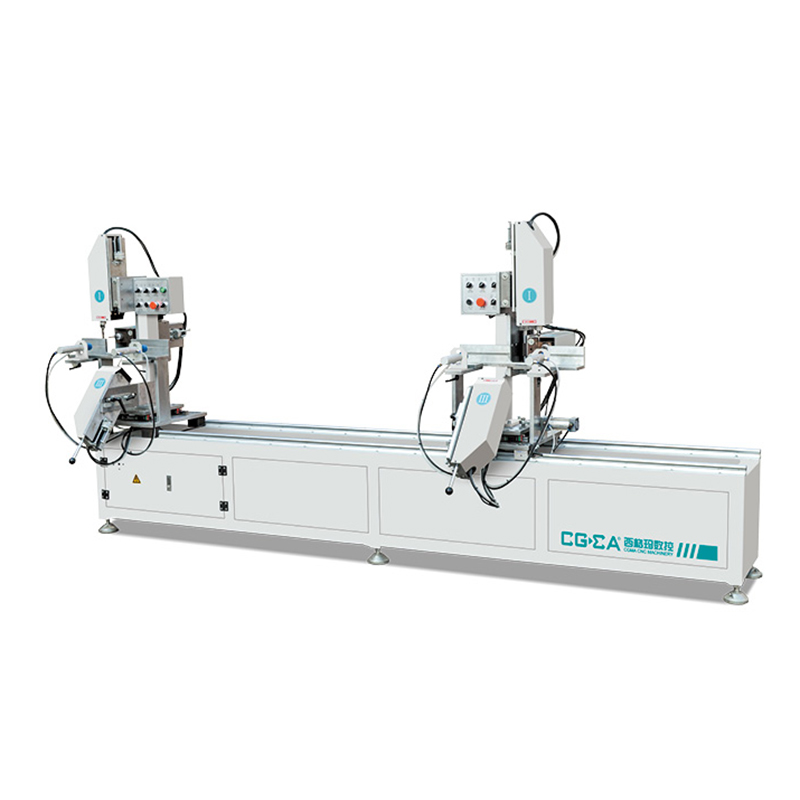

Performance Characteristics

● This machine is two-axis and three-cutters structure,which is used for clean 90° outer corner,the upper and lower welding tumor of the uPVC window and door frame and sash.

● This machine has the functions of sawing milling,broaching.

● This machine is adopted with servo motor control system and high repeated positioning accuracy.

● This machine is equipped with USB port,Using external storage tools can store the processing programs of various specification profiles and can also regularly upgrade the system,etc.

● It has teaching and programming functions, programming is simple and intuitive, and the two-dimension processing program can be set by the CNC programming.

● It can realize the arc difference compensation and the diagonal line difference compensation, which can meet the needs of various profile processing.

Product Details

Main Components

|

Number |

Name |

Brand |

|

1 |

Low-voltage electricalappliances | Germany·Siemens |

|

2 |

Servo motor,Driver | France·Schneider |

|

3 |

Button,Rotary knob | France·Schneider |

|

4 |

Air tube(PU tube) | Japan·Samtam |

|

5 |

Proximity switch | France·Schneider/Korea·Autonics |

|

6 |

Standard air cylinder | Sino-Italian joint venture·Easun |

|

7 |

Phase sequence protector device | Taiwan·Anly |

|

8 |

Solenoid valve | Taiwan·Airtac |

|

9 |

Oil-water separate (filter) | Taiwan·Airtac |

|

10 |

Ball screw | Taiwan·PMI |

Technical Parameter

|

Number |

Content |

Parameter |

|

1 |

Input power | AC380V/50HZ |

|

2 |

Working pressure | 0.6~0.8MPa |

|

3 |

Air consumption | 100L/min |

|

4 |

Total power | 2.0KW |

|

5 |

Spindle motor speed of disc milling cutter | 2800r/min |

|

6 |

specification of milling cutter | ∮230×∮30×24T |

|

7 |

Height of profile | 30~120mm |

|

8 |

Width of profile | 30~110mm |

|

9 |

Quantity of tools | 3 cutters |

|

10 |

Main dimension (L×W×H) | 960×1230×2000mm |

|

11 |

Main engine weight | 580Kg |

Packing Pictures

-

3-head White uPVC Profile Welding Machine

-

4-head White uPVC Profile Welding Machine

-

CNC Double Zone Screw Fastening Machine for uPV...

-

CNC Glazing Bead Cutting Center for uPVC Window...

-

CNS Double Head Cutting Saw for PVC profile

-

Double Head Cutting Saw for uPVC Profile

-

Double-Head Cutting Saw for Aluminum and PVC Pr...

-

End Milling Machine for Aluminum and UPVC profile

-

Glazing Bead Cutting Saw for Aluminum and PVC W...

-

PVC Window and Door CNC High-efficiency Corner ...

-

PVC Window and Door 4-head Seamless Welding Mac...

-

PVC Profile Water-slot Milling Machine

-

PVC Window and Door V-shaped Cleaning Machine

-

uPVC Profile CNC Automatic Cutting Center

-

uPVC Profile Two-head Automatic Water-slot Mill...