Performance Characteristic

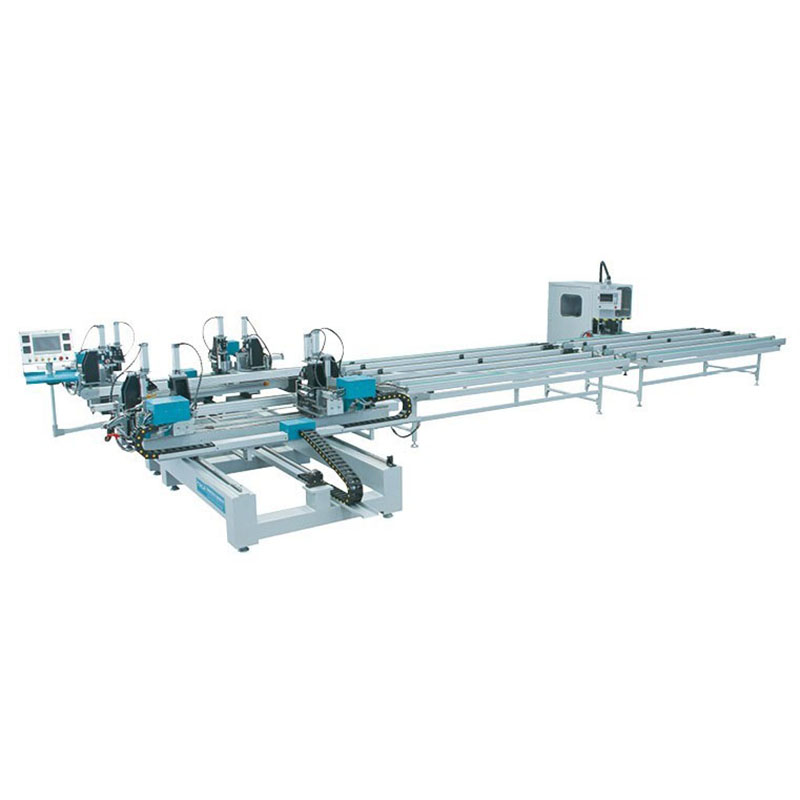

● This production line is consist of the welding unit,conveying unit and corner cleaning unit, and used for complete the welding ,conveying and corner cleaning of uPVC window and door.

● Welding unit:

① The welding unit is layout in horizontal,once clamping can complete th e welding of a rectangular frame,stable and reliable welding,It can also realize the function of welding size error compensation,the precision of welding products is high.

② Using the torque monitoring technology ,through the torque monitoring function of the servo system, the four corner automatically pre-tighening to ensure the welding accuracy.

③ Conversion between seam and seamless adopt the method of dismount press plate to fixed the gab of welding , which ensures welding strength and stability.

● Corner cleaning unit:it equipped with three-axis and six-cutter servo control system,automatically realize rapid cleaning of almost all welding seam of the uPVC window.

Main Components

|

Number |

Name |

Brand |

|

1 |

Low-voltage electricalappliances | Germany·Siemens |

|

2 |

PLC | France·Schneider |

|

3 |

Servo motor,Driver | France·Schneider |

|

4 |

Button,Rotary knob | France·Schneider |

|

5 |

Proximity switch | France·Schneider |

|

6 |

Relay | Japan·Panasonic |

|

7 |

Air tube(PU tube) | Japan·Samtam |

|

8 |

AC motor drive | Taiwan·Delta |

|

9 |

Standard air cylinder | Taiwan· Airtac |

|

10 |

Solenoid valve | Taiwan·Airtac |

|

11 |

Oil-water separate (filter) | Taiwan·Airtac |

|

12 |

Ball screw | Taiwan·PMI |

|

13 |

Rectangular linear guide | Taiwan·HIWIN/Airtac |

|

14 |

Temperature-controlled meter | Hong Kong·Yudian |

|

15 |

High speed electricspindle | Shenzhen·Shenyi |

|

16 |

Low-voltage electricalappliances | Germany·Siemens |

Technical Parameter

|

Number |

Content |

Parameter |

|

1 |

Input power | AC380V/50HZ |

|

2 |

Working pressure | 0.6~0.8MPa |

|

3 |

Air consumption | 200L/min |

|

4 |

Total power | 15KW |

|

5 |

Spindle motor speed of disc milling cutter | 0~12000r/min(frequency control) |

|

6 |

Spindle motor speed of end mill | 0~24000r/min(frequency control) |

|

7 |

Specification of right angle drilling and milling cutter(diameter×handle diameter×length) | ∮6×∮7×80 |

|

8 |

Specification of end mill(diameter×handle diameter×length) | ∮6×∮7×100 |

|

9 |

Height of profile | 25~130mm |

|

10 |

Width of profile | 25~120mm |

|

11 |

Range of machining size | 430×580mm~2400×2600mm |

|

12 |

Dimension (L×W×H) | 12500×5500×1900mm |