These days, everyone’s really looking for high-quality, energy-efficient windows and doors, right? That demand has actually pushed a lot of cool advancements in manufacturing tech. One gadget that really stands out is the CNC Reinforcement Screw Drilling Machine for PVC win-doors—it’s a game-changer. Not only does it make drilling way more precise, but it also helps ensure that the finished products are sturdy and reliable. In such a competitive industry, Jinan CGMA CNC Machinery Co., Ltd. has really made a name for itself. They offer a wide variety of equipment, from UPVC door and window processing machines to aluminum profile machinery. By incorporating state-of-the-art CNC tech, their machines make production smoother, cut down on waste, and boost overall quality—setting manufacturers up for success as the market keeps changing and evolving.

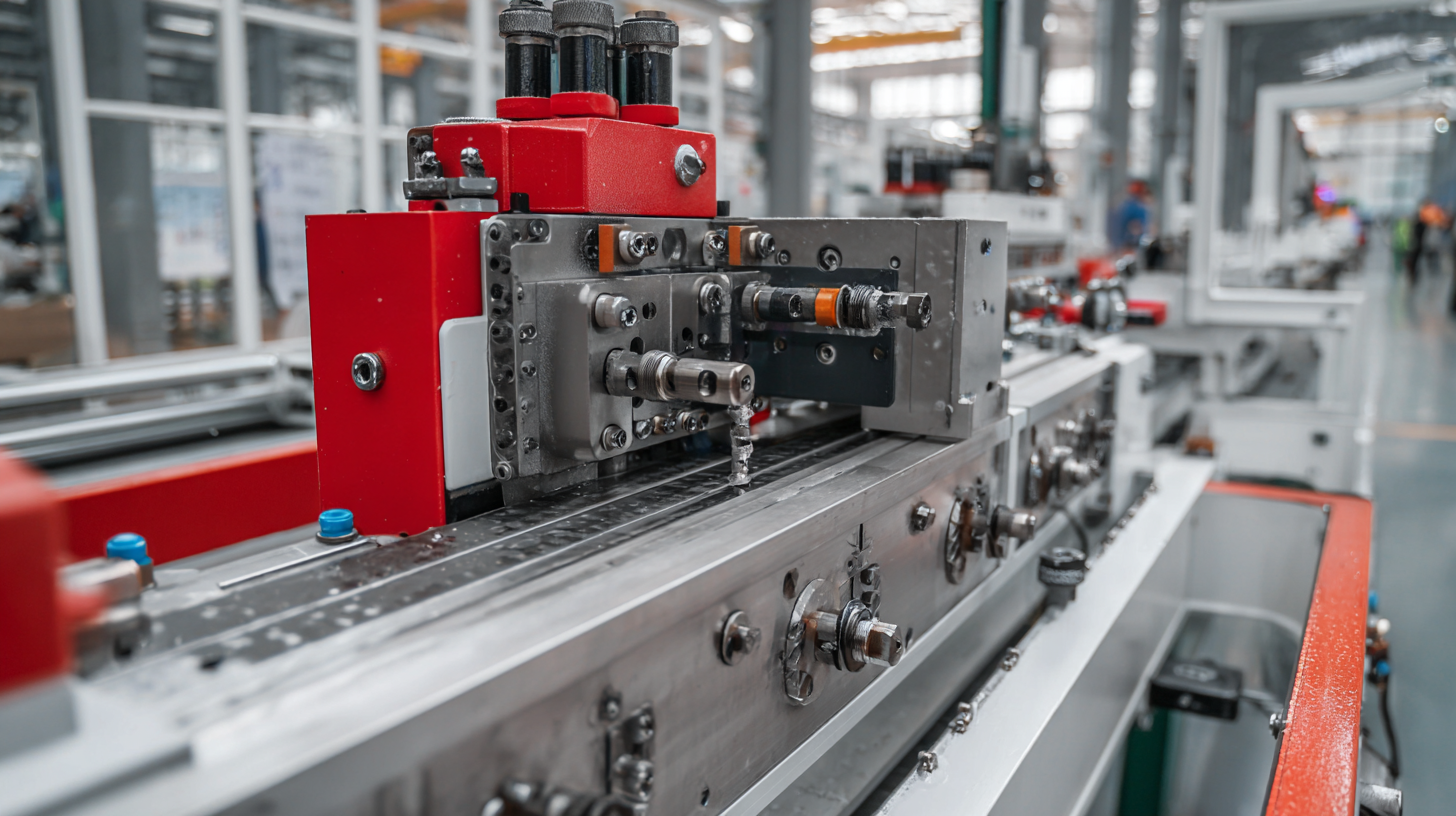

CNC reinforcement screw drilling machines are pretty much essential when it comes to making PVC windows and doors these days. These guys are built to boost both precision and speed during drilling, which is super important to make sure all the parts fit perfectly together. Thanks to computer numerical control (or CNC), these machines can handle even complex drilling tasks with really high accuracy, cutting down on mistakes that you’d probably see with manual drilling. It’s a game-changer, honestly.

But it’s not just about accuracy—these machines also make the production process way smoother. You can program them to drill multiple holes in all kinds of patterns, so handling different design specs becomes a walk in the park. This flexibility not only speeds things up but also helps save materials, which is great for the environment and your wallet. As everyone's craving more custom, high-quality PVC windows and doors, having CNC drilling tech in the mix is pretty much a must if you want to stay competitive in this industry. It’s all about staying ahead and making quality stuff, right?

If you're in the business of making PVC windows and doors, you've probably heard that CNC reinforcement screw drilling machines are kinda game-changers. They’re super precise and efficient — way better than the old-school methods, honestly. One of the coolest parts? The automation. These machines can do a lot on their own, which speeds up production quite a bit. I read somewhere that, according to MarketsandMarkets, automation can bump up productivity by around 30%. That’s huge because it means companies can handle more orders without sacrificing quality.

And get this — these CNC machines aren’t just fast; they’re also versatile. They can handle complex drilling patterns and different hole sizes with crazy accuracy.

That not only makes the whole process smoother but also cuts down on wasted material.

Statista points out that CNC machining can slash waste by up to

25%, which is pretty good for both the planet and your budget.

And get this — these CNC machines aren’t just fast; they’re also versatile. They can handle complex drilling patterns and different hole sizes with crazy accuracy.

That not only makes the whole process smoother but also cuts down on wasted material.

Statista points out that CNC machining can slash waste by up to

25%, which is pretty good for both the planet and your budget.

Pro tip: Make sure you keep those CNC machines well-maintained. Regular check-ups help them perform at their best and last longer. Also, investing in good design and simulation software can really help your team spot potential issues early — saving you time and headaches down the line.

CNC technology has really changed the game in manufacturing, especially when it comes to making PVC windows and doors. One of the biggest perks of using CNC reinforcement screw drilling machines is how precise they are. These machines are set up to drill with incredible accuracy, making sure that all the screw holes are perfectly aligned and evenly sized. That kind of accuracy not only boosts the strength and durability of the windows and doors but also cuts down on mistakes from human error. Plus, it makes the whole production process smoother and faster.

On top of that, CNC machines can really boost efficiency. Unlike the old-school methods that could take forever and often needed a bunch of workers, these machines handle the drilling automatically. They work quickly, reducing the downtime between steps, which means companies can crank out more units without sacrificing quality. Basically, if you're looking to modernize your operations and get things done quicker, CNC technology is a super smart choice.

CNC drilling machines really are a game-changer when it comes to making PVC windows and doors. They boost precision and quality in a way that’s hard to beat. Thanks to advanced computer-controlled tech, these machines can drill every screw hole with incredible accuracy, cutting down on mistakes that humans might make. And that’s such a big deal because, in PVC projects, even tiny misalignments can cause problems — like inefficient assembly or weak spots in the structure. As more folks are looking for high-quality PVC products, the demand for reliable CNC drilling systems is only going up.

On a broader note, the global market for CNC router machines was valued at around USD 691 million in 2023. And it’s not just standing still — experts expect it to grow at about 3.5% annually from 2024 through 2030. That shows how much industries, including PVC manufacturing, are leaning on CNC tech more and more. The improved precision really helps in upping product quality, but it also makes production faster and smoother. So, manufacturers can keep up with the higher standards the market demands. With CNC technology constantly evolving, the future for PVC window and door manufacturing looks pretty bright. All in all, these sophisticated machines are undeniably crucial in pushing the industry forward.

When you're dealing with the manufacturing of PVC windows and doors, the kind of drilling tech you choose really matters – it can make a big difference in both efficiency and the quality of your products. CNC reinforcement screw drilling machines? They really stand out from the traditional methods because they’re faster and much more precise. I mean, with regular drilling, you might get some uneven holes or the depth might not be perfect every single time. But CNC machines, which are controlled by computers, follow exact specs, so each hole comes out just right. That means fewer mistakes, less scrap, and a final product you can trust.

A quick tip—if you're switching from old-school methods to CNC, make sure your team gets properly trained. Getting folks familiar with the software and machine capabilities can seriously boost your production speed and cut down on setup hassles. And don’t forget to keep those machines maintained regularly — it helps avoid downtime and makes sure they last longer.

Another cool thing about CNC machines is they can handle complex designs that would probably be a pain with traditional tools.

They can do all kinds of intricate patterns and easily switch between different materials.

If you’re thinking about growing your business or offering more diverse products, investing in CNC tech could really be a game changer.

Quick tip—look into adaptive software that allows easy updates with new designs. It can make your entire process even smoother. And staying on top of industry trends can give you some great insights into how to position your products in a competitive market.

As the window and door industry keeps evolving, it’s pretty exciting to see how CNC screw drilling tech is about to shake things up in manufacturing. One of the biggest shifts? The rise of automation and AI being integrated into CNC machines. This isn’t just about precision — it’s also about these machines being smarter and more adaptable to different production needs. Thanks to clever algorithms, they can analyze data on the fly, tweaking drilling patterns for different PVC profiles and even handling design changes with barely any downtime. Honestly, it’s like giving these machines a little extra brain power!

On another note, there’s a big push toward sustainability. Companies are really focusing on eco-friendly materials and energy-saving machinery. Nobody wants to be left behind, right? So, we’re seeing innovations that cut down on energy use without sacrificing performance. Plus, improvements in tool lifespan and recycling acrylic chip waste mean less mess and fewer resources wasted during production. All these trends? They’re helping manufacturers stay competitive while also making the industry a lot greener and more responsible — which is pretty cool, if you ask me.

In the pursuit of enhancing aluminum win-door production, the choice of equipment plays a pivotal role, particularly when it comes to corner crimping. Our single-head corner crimping machines stand out as professional solutions specifically designed for efficiently crimping and connecting 45° angle frames of aluminum windows and doors. These machines are engineered to meet stringent production demands, ensuring that every crimp is executed with precision and speed.

Equipped with a large diameter hydraulic oil pump, our corner crimping machines operate at an impressive rate of four corners per minute, significantly increasing production efficiency. With a crimping height of 160mm, they are versatile enough to handle various profiles in the aluminum window and door manufacturing process. Additionally, the ability to customize crimping knives based on profile section drawings ensures that every machine adapts seamlessly to the unique specifications of your projects, resulting in superior finished products that reflect quality craftsmanship.

: CNC reinforcement screw drilling machines enhance precision and efficiency in the drilling process, ensuring seamless fitting of components and reducing the risk of errors associated with manual methods.

They utilize advanced computer numerical control technology to drill screw holes with maximum accuracy, minimizing human error, which is crucial for maintaining quality in PVC products.

CNC drilling machines can be programmed to drill multiple holes in various configurations, streamlining workflows, accelerating production, and minimizing material waste.

Precision is critical because even minor discrepancies can lead to inefficiencies and structural weaknesses in the final product.

The global CNC router machine market is valued at approximately USD 691.0 million in 2023, with a projected steady growth rate of 3.5% CAGR from 2024 to 2030.

By minimizing material waste through precise drilling, CNC technology supports environmental sustainability while also maintaining cost-effectiveness for manufacturers.

The rising demand for customized and high-quality PVC windows and doors underscores the need for reliable CNC drilling systems to meet these standards effectively.

With continuous advancements in CNC technology, the future looks promising for PVC window and door production, highlighting the essential role of these sophisticated machines in the industry.

Yes, CNC drilling machines are versatile and can handle various design requirements with ease, making them essential for modern manufacturing processes.

Enhanced precision delivered by CNC drilling machines not only improves product quality but also boosts production efficiency, allowing manufacturers to effectively meet rising market standards.

So, I was reading this blog about the CNC Reinforcement Screw Drilling Machine for PVC windows and doors, and honestly, it got me thinking about how much these machines are transforming modern manufacturing. They’re not just fancy gadgets—they really help boost efficiency, precision, and overall quality during production. I mean, features like automated drilling and high-speed processing really stand out and make a huge difference, right? That’s what sets CNC technology apart from the old-school, manual methods.

Plus, the blog points out some pretty compelling perks of using CNC machines—things like cutting down labor costs, making sure every product looks consistent, and even handling more complicated designs with ease. Looking ahead, it sounds like ongoing advancements in CNC screw drilling tech are going to shake things up even more in the window and door world. And honestly, Jinan CGMA CNC Machinery Co., Ltd. is right there at the forefront, pushing these innovations and helping raise the bar for production quality across the board. It’s pretty exciting stuff!